Microchannel condensers have revolutionized the way heat exchange occurs in various applications, particularly in the HVAC and refrigeration sectors. These compact devices utilize a unique design that significantly enhances thermal efficiency while minimizing the amount of refrigerant required. This article delves into the intricate mechanisms that govern microchannel condensers and their advantages over traditional designs.

The Basic Principles of Microchannel Technology

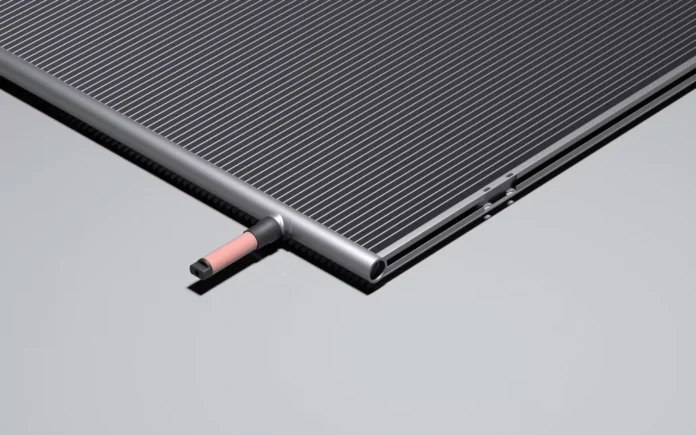

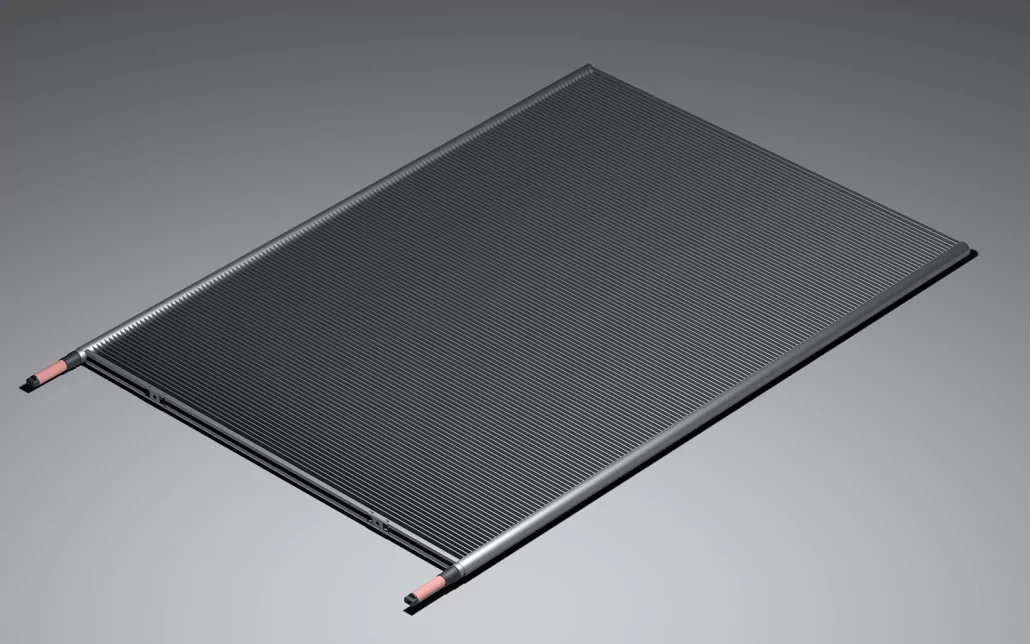

Microchannel condensers are designed with multiple small channels, allowing for a larger surface area to volume ratio compared to traditional fin-and-tube condensers. This configuration facilitates more effective heat transfer due to the increased interaction between the refrigerant and the ambient air.

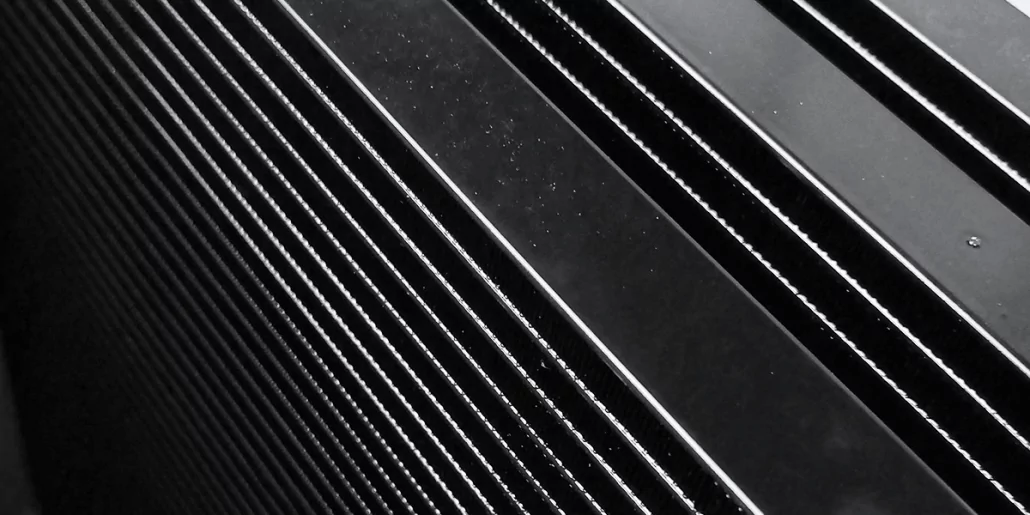

The operation of these condensers begins with the vaporized refrigerant entering the microchannels, where it is cooled and condensed into liquid form. The small channel diameter promotes turbulent flow, which enhances heat transfer rates. The microchannel design also promotes a more uniform distribution of refrigerant, preventing hot spots that can reduce efficiency.

Enhanced Surface Area and Heat Transfer

One of the standout features of microchannel condensers is their enhanced surface area. The geometry of microchannels allows for more refrigerant to be in contact with the heat exchange surface at any given moment. This leads to improved heat transfer coefficients, which are often two to three times higher than those found in traditional condensers.

In practical scenarios, this means that microchannel condensers can achieve the same cooling effect as larger conventional units while occupying a significantly smaller footprint. This is particularly beneficial in applications where space is a constraint, such as in residential air conditioning systems or compact refrigeration units.

Material Considerations

Microchannel condensers are typically constructed from aluminum, which offers several advantages over copper and other materials. Aluminum not only provides excellent thermal conductivity but is also lightweight and resistant to corrosion. The use of aluminum in microchannel designs reduces overall system weight, improving efficiency in transport and installation.

Furthermore, the manufacturing processes used for aluminum microchannels allow for tighter tolerances and better control over the geometry of the channels, ensuring optimal performance. For instance, the application of advanced coating technologies can enhance the durability and efficiency of the heat transfer surfaces.

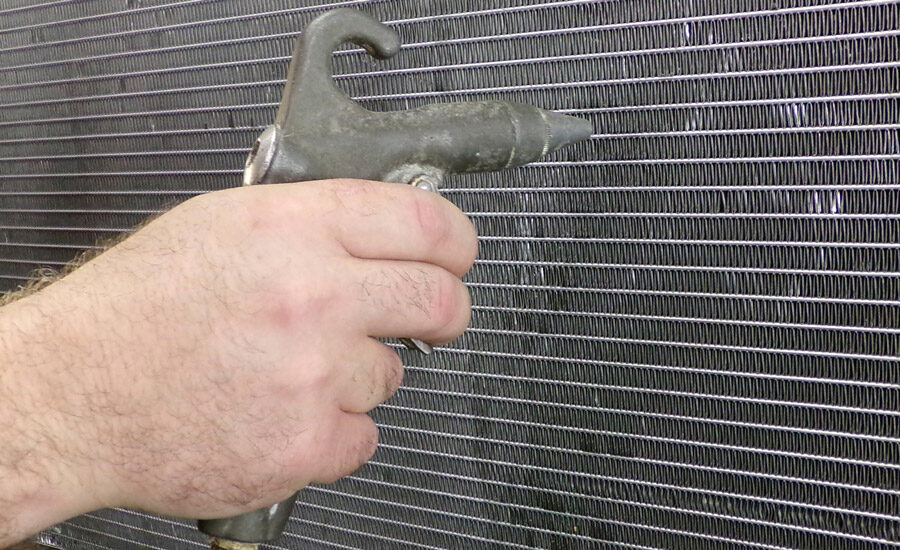

Maintenance and Sustainability

The compact size and design of microchannel condensers also simplify maintenance. Fewer parts and a reduced likelihood of refrigerant leaks result in lower maintenance costs over time. From a sustainability standpoint, the efficient use of refrigerants translates to lower environmental impact, aligning with global initiatives to reduce greenhouse gas emissions.

For manufacturers, transitioning to microchannel condensers can also mean lower operational costs and increased competitiveness in a market that values energy efficiency and eco-friendliness on https://www.kaltra.com.

Applications and Future Trends

Microchannel technology is increasingly being adopted in a variety of applications. From residential air conditioning systems to commercial refrigeration, the versatility of microchannel condensers makes them an attractive option. Industries that require high-performance cooling solutions, such as data centers and process cooling, find microchannel designs particularly advantageous.

Looking ahead, the integration of smart technologies and advanced materials will further enhance the performance and efficiency of microchannel condensers. Innovations in refrigerants and control systems are expected to optimize energy usage and improve system reliability, paving the way for the next generation of HVAC solutions.

A Result

Microchannel condensers exemplify the evolution of heat exchange technology, combining efficiency, space-saving design, and sustainability. As industries continue to prioritize energy efficiency and environmental responsibility, the adoption of these advanced condensers is set to grow. Their unique mechanisms not only provide exceptional performance but also align with global trends towards greener technologies, ensuring their relevance in the future of HVAC and refrigeration applications.