Project Management can be said as an artwork of managing the projects by having a control on cost, time, and quality of the project. There are many different aspects of quality that are based on different levels including products, organizations, etc. of the project.

According to the PMBOK(2009) guide of project management, quality is defined as the degree where the requirements of the project meeting. It is used as an operative word that helps in fulfilling all the requirements of the project.

In this article, we have provided all the information about the Total Management Quality and Quality Control.

Total Quality Management

Talking about the word Total Quality Management, the word is quite uncertain as it has been taken from the multi-edition book of The Japanese Way having the titles, what are Total Quality Control and Total Quality Control.

Now, you might be confused or have a question like what does one mean by Total Quality Management? Talking about it, Total Quality Management stands for the management approach that gives the long-term success of the project by the customer satisfaction.

Total Quality Management offers customer satisfaction by focusing on improved processes. This process includes a cycle known as PDCA, mainly, Plan, Do, Check, and Act. Total Quality Management does not implement its project to the entire organization but it is often managed by individuals.

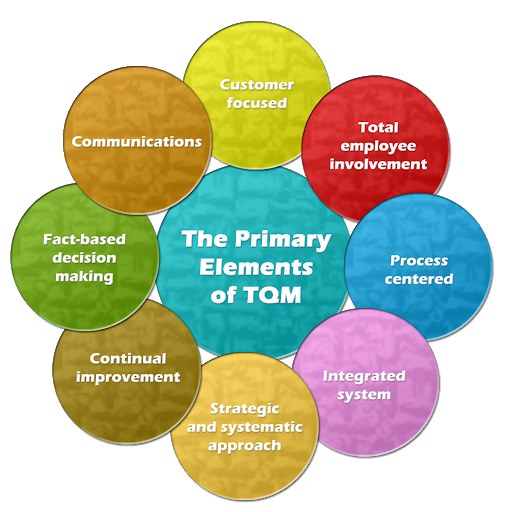

Principles of Total Quality Management

According to Vinsys, there are very few principle differences between Total Quality Management and Quality Control. But the principles are very important as it is very useful to project management. The principles include:

- Adopts a systematic and strategic approach

- Ensure Communication with stakeholder

- Integrate the organization system

- Commitment to continuous improvement

Designs of Experiment and Statistical Techniques of TQM

Talking about the Designs of Experiments, it is mainly used for the focus that brings continuous improvements. The best level of control factors is determined here including all the 8 major steps of planning, conducting, and evaluating the results of the experiment.

In TQM, the statistical techniques are used for the process capability and analysis of the project. It tries to meet the expectations of the client by relating the assessment capabilities of the processes or the machine. The main focus of this technique is to reduce the variations.

Performance goal and certification of TQM

The measurement of the goals of TQM is done based on TQM concepts that include Focus, Leadership, Teamwork, Improvement, Measurement, and Benchmarking. This all will surely help the organization to translate customers’ needs into a matrix.

Certification of Total Quality Management includes two main certificates. They are:

- Total Quality Management Professional (TQMP)

- Lean Six-Sigma Certifications

The Approach of Total Quality Management

The Approach of TQM is built with three parts. The system, Method, and Purpose are the three parts.

- System: System over here is for all the individuals of all the divisions at every level.

- Method: Usually, method over here refers to two methods, Management and Analytical.

- Purpose: It describes the purpose of TQM that includes, the Quality, Safety, Cost, Time, and Delivery of the project.

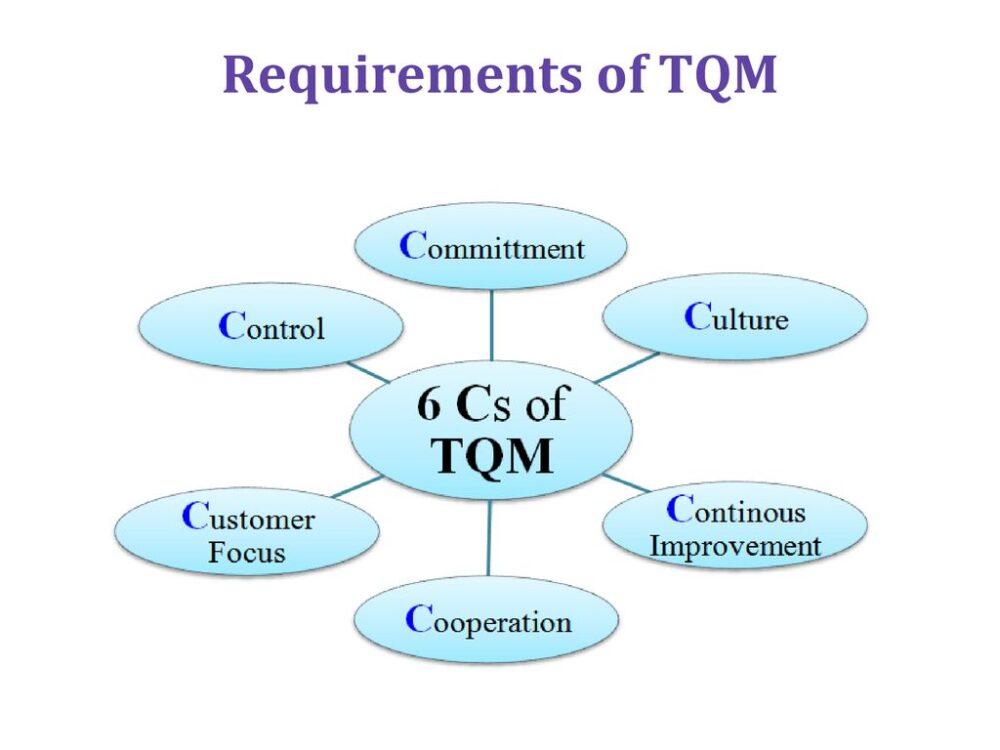

6 C’s of TQM

- Commitment

- Culture

- Continuous Improvement

- Cooperation

- Customer Focus

- Control

Quality Control

Many of you might not be having detailed information regarding Quality Control. Let’s discuss Quality Control. Quality Control is the process that helps in reviewing the quality of all the factors that undergo production.

Quality Control always makes sure that the factor that is being produced should always meet the technical standard of quality. How this surety could be possible? By the involvement of the physical checking of the activities, it could meet the customer’s requirements at each stage of production by making the surety.

As compared to TQM, Quality Control also possess cycle. The cycle includes the testing, packing, and shipping of the material manufactured. So, the main aim of Quality Control is to focus on the identification of the defect as it is product-oriented.

The quality of the product is assured with the help of Quality Control.

Principles of Quality Control

The principles of quality control are very important as it helps in the detection of the defect occurred in the product. The principle of Quality Control includes:

- Leadership and Organizational Structure

- Process and System Based Approaches

- Focus and Customers

- Industry Standard

- Clear Policies

Designs of Experiment and Statistical Techniques of Quality Control

The design of experiments used here is mainly designed for the focus on the product manufactured. The value of a parameter or the group of parameters is controlled by the test that deals with Planning, Conducting, Analyzing, and Interpretation by evaluating the factors.

The Statistical Techniques includes the 7 quality control methods. 7 tools used is:

- Ishikawa Diagram

- Chart Control

- Chart Pareto

- Histogram

- Check Sheet

- Scatter Diagram

- Stratification

The main focus of this is to establish a cause-effect relationship among variables caused.

Performance Goal and Certification of Quality Control

The measuring of the goals of the Quality Control is done by Quality Concepts. The goals are set for the reduction of the defects such as:

- Current Defects

- Defect Rates

- Defect Density

The goals help this defect to get reduced by a certain percentage in a specified time.

If we see the certification of Quality Control, then there is a certification course naming, Quality Control Certification or Quality Assurance Certification

This certification helps the students with the quality control techniques and methods that are being implemented in the field of industrial manufacturing. This certification course helps the candidate to acquire a job in Industrial Engineering Technology, Architecture, Biological Science, etc.

One can easily get the job as a Quality Control Manager, Quality Control Engineer, Assistant Manager Control after having the Quality Control Certification. Usually, quality control is handled by the different sets of people and not by any individual working in an organization.

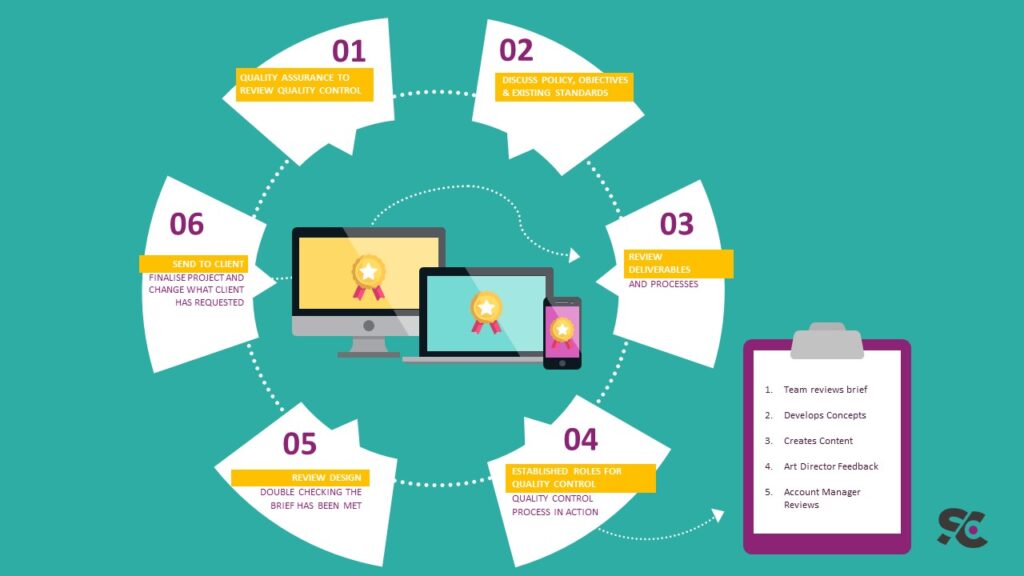

Process of Quality Control

Mainly, Quality Control includes three major processes. They are:

- Incoming Quality Control (IQC): Through IQC, the inspection of arrived raw material and components from suppliers is done.

- In-Process Quality Control (IPQC): This helps in the detection and handling of the problem beforehand.

- Outgoing Quality Control (OQC): This helps in the checking of the delivery of the defect-free product just before the shipping.

Hence, the article contains all the information about Total Quality Management Vs Quality Control. I hope this article helped you to have a clear difference between both.