Tempered glass has become an essential material in modern society. From smartphones to car windows, this type of glass provides strength, durability, and safety. This article will delve into the science behind tempered glass, exploring the manufacturing process, its characteristics, and the advantages of using it. Finally, we will discuss the importance of tempered glass in today’s world.

The Process of Manufacturing Tempered Glass

Step 1: Preparing the Raw Materials

The journey of becoming tempered glass begins with the preparation of raw materials. A typical tempered glass manufacturer starts by sourcing high-quality silica sand, soda ash, limestone, and other trace elements. These materials are combined in precise proportions to create a homogeneous mixture, which is then heated to a high temperature in a furnace. This process, known as melting, transforms the raw materials into molten glass.

Step 2: Forming and Annealing

Once the glass reaches its molten state, it is poured onto a large, flat surface, usually a bed of molten tin. This process, known as float glass production, ensures that the glass has a smooth and uniform thickness. As the glass cools down, it solidifies and takes on its final form.

To relieve internal stresses caused by the cooling process, the glass undergoes a process called annealing. During annealing, the glass is heated to a specific temperature and then cooled gradually. This process allows the glass to reach a state of equilibrium, making it less susceptible to breakage.

Step 3: Cutting and Edge Treatment

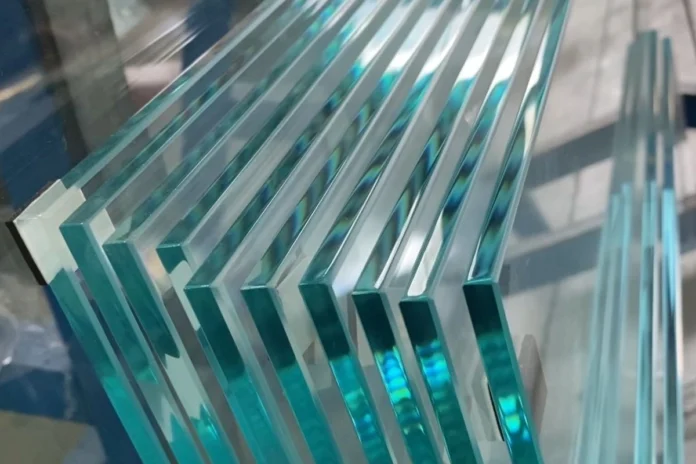

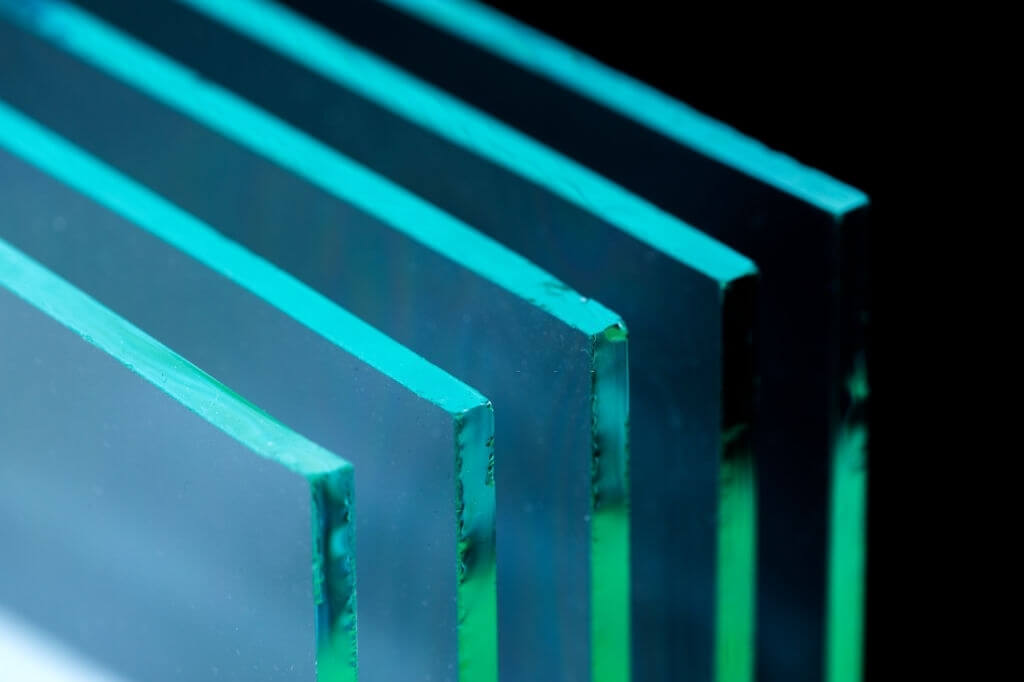

After the annealing process, the glass is cut into the desired size and shape. A tempered glass manufacturer uses advanced cutting technology, such as computerized numerical control (CNC) machines, to ensure precise and accurate cuts. Once the glass has been cut, its edges are treated to remove any sharpness and reduce the risk of injury. This process typically involves grinding, polishing, or beveling the edges.

Step 4: Tempering

The final and most crucial step in the manufacturing process is tempering. During this stage, the glass is heated to a high temperature, usually around 620 degrees Celsius (1,148 degrees Fahrenheit). After reaching the desired temperature, the glass is rapidly cooled by blasting it with high-pressure air. This process induces compressive stress on the surface of the glass while the center remains in tension. As a result, tempered glass is much stronger and more resistant to breakage than regular glass.

Properties and Characteristics of Tempered Glass

1. Strength and Durability

One of the most notable properties of tempered glass is its increased strength and durability. Compared to regular glass, tempered glass is four to five times stronger, making it an ideal choice for applications where safety and durability are paramount. This strength comes from the compressive stress created during the tempering process, which increases the glass’s resistance to breakage.

2. Safety

When it comes to safety, tempered glass is a clear winner over regular glass. In the event of breakage, tempered glass shatters into small, relatively harmless pieces, reducing the risk of injury. This is in stark contrast to regular glass, which can break into large, sharp shards that can cause significant harm. This safety feature makes tempered glass an excellent choice for various applications, such as automotive windows and glass doors.

3. Resistance to Thermal Stress

Another characteristic of tempered glass is its resistance to thermal stress. The tempering process makes the glass more resistant to sudden changes in temperature, reducing the risk of breakage caused by thermal stress. This property is particularly useful in applications where the glass may be exposed to fluctuations in temperature, such as oven doors, fireplace screens, and glass facades.

Benefits and Advantages of Using Tempered Glass

1. Improved Safety

As mentioned earlier, the safety features of tempered glass make it an ideal choice for a wide range of applications, especially in situations where breakage could pose a significant risk. By shattering into small, harmless pieces, tempered glass reduces the likelihood of injury and property damage.

2. Enhanced Durability

The increased strength and durability of tempered glass make it well-suited for applications where regular glass may not hold up. For instance, tempered glass is commonly used in commercial building facades, where it can withstand high winds and other environmental stressors. Additionally, the use of tempered glass in smartphones and other electronic devices helps protect screens from damage caused by drops and impacts.

3. Resistance to Thermal Stress

Tempered glass’s ability to withstand temperature fluctuations makes it an excellent choice for applications where thermal stress may be a concern. For example, tempered glass is often used in oven doors, fireplace screens, and even spacecraft windows to protect against the extreme temperature changes these environments can experience.

Elevating Aesthetic and Functionality with Glass Splashbacks

Amid the myriad applications of tempered glass, an innovative addition to the modern landscape emerges – the integration of tempered glass splashback. These sleek and versatile panels not only harness the inherent strength and safety of tempered glass but also introduce an element of design sophistication.

Incorporating glass splashbacks into kitchens and bathrooms amplifies the practical advantages of tempered glass. These panels provide a hygienic, easy-to-clean surface that is resistant to moisture and stains. Moreover, the reflective properties of glass splashbacks extend the illusion of space, making them an ideal choice for compact areas like bathrooms.

In kitchens, tempered glass splashbacks redefine the aesthetics of culinary spaces. They serve as protective barriers against cooking splatters while becoming canvases for creative expression. Glass splashbacks can be customized with a spectrum of colors, patterns, or even digital prints, adding a personalized touch to the heart of the home.

Similarly, in bathrooms, glass splashbacks merge function and style seamlessly. Their resilience against humidity and water exposure ensures longevity, while the play of light on their surfaces contributes to an ambient atmosphere. With a plethora of design options, glass splashbacks effortlessly integrate into diverse bathroom themes, enhancing the visual appeal of limited spaces.

The Importance of Tempered Glass in Modern Society

In today’s fast-paced world, the demand for stronger, more durable materials continues to grow. Tempered glass has become a go-to solution for a variety of industries, providing increased safety and durability in various applications.

In the automotive industry, tempered glass is used for side and rear windows to protect passengers in the event of an accident. In construction, tempered glass is used in commercial building facades, glass doors, and even residential windows to offer increased strength and safety. Similarly, tempered glass is used in smartphones, tablets, and other electronic devices to protect screens from damage and improve their overall durability.

In summary, tempered glass has become an essential material in modern society due to its numerous advantages over regular glass. Its manufacturing process ensures that the final product is strong, durable, and safe, making it an ideal choice for a wide range of applications. As technology continues to advance, and the demand for safer, more durable materials grows, tempered glass will continue to play a crucial role in shaping the world around us.