Having the right tools determines how fast and accurate you can finish a project. This statement is very true in a machinist workshop. Unfortunately, due to the varying types of jobs, there is no universal toolset for each machinist. However, there are a few tools that you should always have at hand as a modern machinist to facilitate the production of items.

Regardless of the level of skill, every machinist should aim at achieving precision, accuracy, and premium quality in their job. Thanks to the advanced technology, you can quickly achieve all this with the right tools. However, buying proper machines can be expensive. Therefore, you need to get it right the first time. This article will take you through five key tools for a modern machinist.

Digital Calipers

As a machinist, this is probably one tool that you use in your day to day activities. It is efficient whenever you need to get small measurements. Although these tools vary in shapes, sizes, and features, they use the same principle to achieve their purpose. You achieve this by resting their opposing tips at the beginning and end of the space that you are measuring. There are several types of calipers, including:

- Vernier calipers: These tools come with a flat bar on which the two tips slide. It uses a graded scale to measure the distance.

- Dial caliper: While they work as Vernier calipers, the dial calipers displays the readings on a dial, which makes them easy to read.

- Digital calipers: They feature easy to read digital screens and other sophisticated features that provide their ease of use and precision.

The calipers are crucial tools to make correct measurements of dimensions and thickness. When choosing a digital caliper for your projects, go for a minimum of six inches or even eight inches if you can afford it.

Angle Finders

Project success largely depends on accurate measuring and precise cutting. Angle finder is a practical tool that you can use in various applications in different fields. With digital angle finder at hand, you can effortlessly measure interior and exterior angles. They are also useful when you need to replicate an angle because they store reading for later reference.

An angle finder is a tool that features two jointed arms and a scale that shows readings of angles. By spreading the arms, you can create different angles that are then changed to digital figures. The measurements will be shown on the screen.

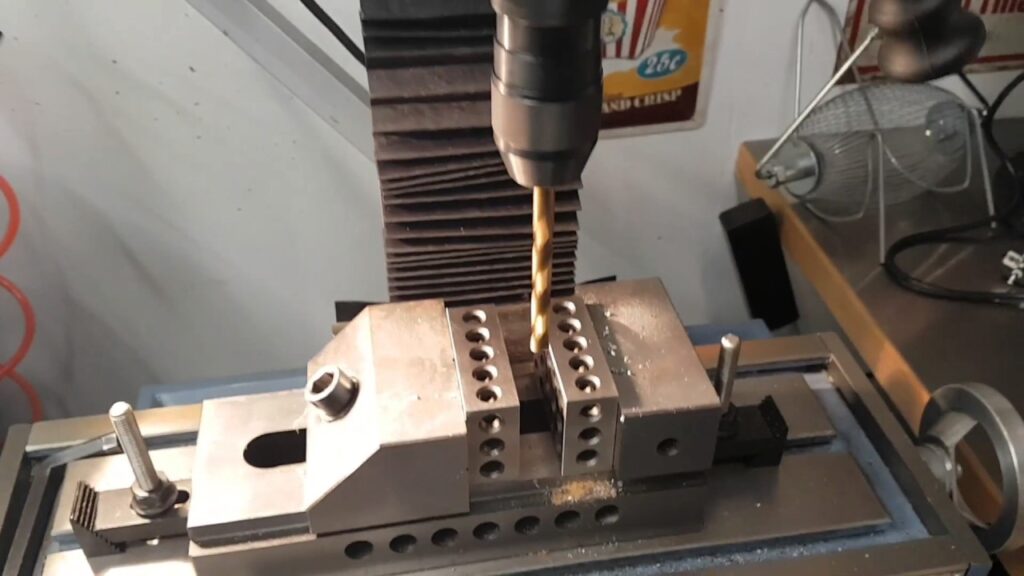

Parallel Blocks

When you are working with metals, you are might encounter the need to elevate your workpiece in a vise or worktable for the purpose of machining. This is where you need the parallel blocks. So, what are these tools? The parallel blocks are rectangular shaped blocks that are constructed of stainless steel, cast iron, and steel. Usually, they come in matching pairs.

These tools come in different designs, such as adjustable parallels and wavy parallels. You can place them underneath or on sides of your workpiece for precision work. Thanks to their ranging sizes and thickness, the parallel blocks are very versatile in their uses. They are perfect when drilling, milling, planning, and many more. Therefore, regardless of the kind of work you are doing, these tools guarantee high-quality performance and results.

Deburring Tool

Deburring is a vital stage of any metal fabrication process. There is a need to smoothen out all the rough edges in a product for safe handling and quality finish. Therefore, you need the right tool to help you with chamfering, deburring, and edge breaking. This is where the deburring tools come in use. Not only does the process improve the functionality of the product, but it also allows the paint to stick and have more consistent thickness.

There are many deburring tools to help you to remove defects surfaces such as narrow slots and hole edges. When you are choosing your deburring tool, you should keep the following in mind:

- The work material

- The finish you require

- The edge radius

- What is the height and thickness of the burrs

An excellent deburring tool is a necessity for a modern machinist toolbox. This tool is a worthy investment because you will save money and time. What is more is that you can utilize it on copper, plastic, aluminum, mild cast iron, steel, nylon, and wood. You can use the rotary design blades to get rid of burrs from edges, tube interiors, these products, and holes.

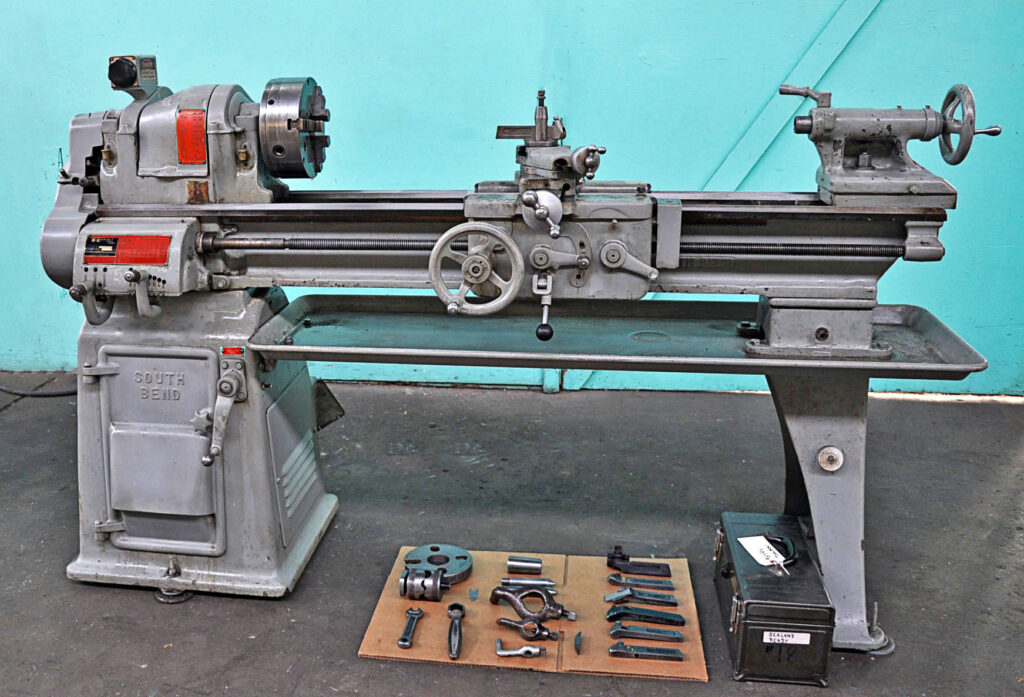

Lathe

This is the father of all machine tools, considering how its mechanical elements have been used to design other tools. As suggested by Lakeside-hire.co.uk, a lathe is a machine tool used for shaping metals and other materials. This basic tool can be used for various purposes like facing, drilling and turning operations. For the purpose of boring and turning, this machine utilizes a single-point cutting device.

When it comes to turning operations, the machine allows you to cut excess metal from the external diameter in the form of chips. Furthermore, you can turn straight or cylindrical shapes, screw heads, grooves, and shoulders.

You can further use lathe is in operations such as counterboring, drilling, countersinking, reaming, and threading. The boring project involves enlarging and finishing a drilled or corded hole. This ensures that the holes are parallel and round.

Final Remarks

Not only do the modern machines speed up the production process, but they also ensure that you attain high-quality results. While these tools perform the same functions and have basic features like the essential tools, they incorporate modifications to allow them to achieve precision fast and consistent. More so, they include ease of use, making them ideal for both beginners and professionals.

As a machinist, you should always strive to achieve accuracy and precision in your work. When you are buying tools, always consider the durability, portability, features, and efficiency of the devices. They go a long way in the quality of your end products.

Although there are various machines in the market, some key tools for a modern machinist include angle finders, parallel blocks, calipers, lathe, and deburring tools. Don’t be tempted to sacrifice efficiency for affordability. Get all the information you need on machinist tools on safedoom.com and enjoy your machining experiences.