In the realm of medical care, the swiftness and efficiency of sterilization processes are of paramount importance. This comprehensive guide delves deep into the intricate world of hospital autoclave sterilizers, seeking to address the question that often arises: “How fast can a hospital autoclave’s sterilization cycle be?”

Throughout this exploration, you will discover the myriad of factors influencing sterilization cycle duration, learn about the latest innovations in autoclave technology, and explore how hospitals can harness the power of rapid sterilization without compromising the effectiveness of this process.

Understanding Hospital Autoclave Sterilizers ─ What is a Sterilization Cycle?

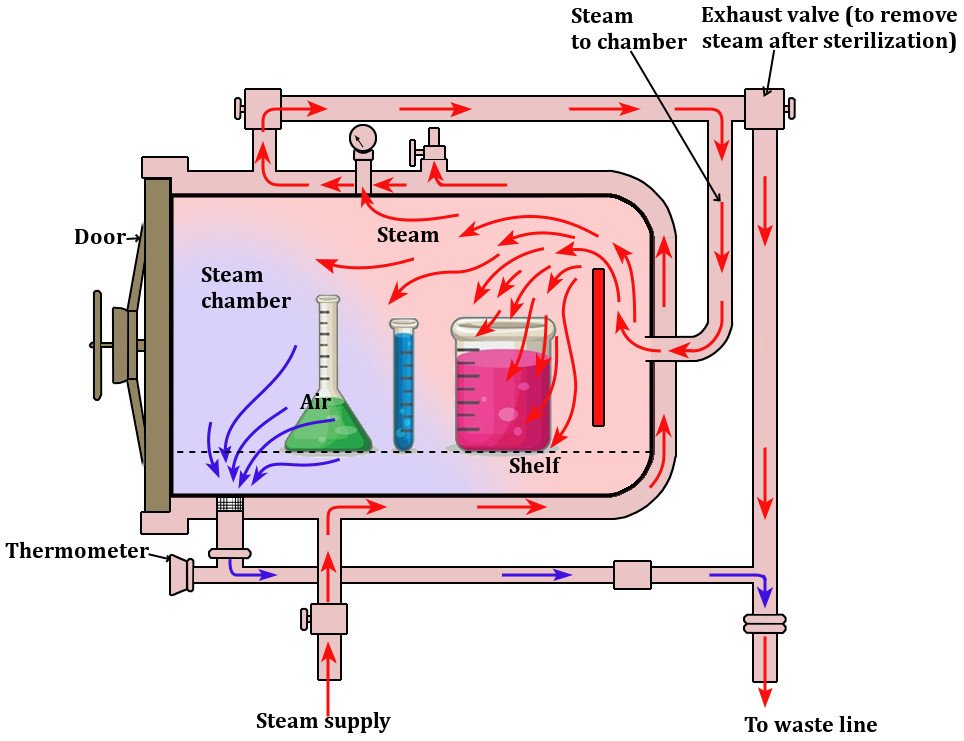

Hospital autoclave sterilizers stand as vital components in safeguarding patient health by ensuring the elimination of harmful microorganisms from medical instruments, equipment, and supplies. Through the utilization of high-pressure steam, these sterilizers achieve the sought-after level of sterilization.

Autoclaves operate based on a process known as steam sterilization. Medical tools inside the autoclave are exposed to high-pressure and high-temperature steam to destroy potentially infectious foreign materials present on their surface, which allows them to be safely reused again.

An autoclave sterilization cycle represents the total amount of time needed for all the steps of this process to be completed. The typical sterilization cycle encompasses various stages, including heating, pressurization, exposure, depressurization, and drying.

Factors Affecting the Speed of an Autoclave Sterilization Cycle

Numerous factors intertwine to influence the speed of an autoclave’s sterilization cycle:

- Load size ─ The scale of items subjected to sterilization directly influences the cycle’s duration. Larger loads often necessitate more time for uniform sterilization.

- Item complexity ─ Items characterized by intricate designs or hard-to-reach surfaces may demand lengthier exposure times to ensure comprehensive sterilization.

- Initial temperature ─ Commencing the cycle with items at an elevated initial temperature can expedite the sterilization process.

- Steam quality ─ The caliber of steam generated within the autoclave significantly impacts both the speed and efficacy of the sterilization cycle.

- Cycle parameters ─ Adjustments to parameters such as temperature and pressure can substantially affect cycle duration. Nevertheless, these adjustments must remain within the confines of safe and effective ranges.

Optimal Autoclave Sterilization Cycle Duration

In the quest for efficient autoclave sterilization, it is vital to strike a harmonious balance between speed and efficacy. Although rapidity holds its significance, the foremost goal of hospital sterilization remains the complete eradication of pathogens. Consequently, determining the optimal duration of a sterilization cycle involves skillfully harmonizing these two factors.

Rapid Autoclave Sterilization Technologies for Faster Cycles

The progression of time has borne witness to the emergence of rapid autoclave sterilization technologies designed to cater to the demands for expeditious turnaround times and faster cycles.

Concepts like “flash sterilization” or “vacuum cycles” endeavor to rapidly sterilize specific instruments. However, it is imperative to note that these methods might not be universally applicable, as certain instruments and materials may necessitate more thorough sterilization processes that take more time.

Innovations in Autoclave Sterilization Technology

As technology evolves, the landscape of autoclave technology experiences continuous innovation. Enhanced steam generation systems, refined heating mechanisms, and pioneering pressure control systems collectively contribute to curtailing cycle times while maintaining the standard of sterilization.

Vacuum Autoclave Vs. Gravity Displacement Autoclave ─ Different Sterilization Cycle Speed

In the quest for faster sterilization cycles, a noteworthy comparison emerges between vacuum autoclaves and gravity displacement autoclaves. Vacuum autoclaves, through the incorporation of vacuum technology, can drastically reduce cycle times. For example, the sterilization cycle of Celitron’s hospital autoclaves can be as fast as 20 minutes.

This is because vacuum cycles enable quicker steam penetration and more efficient air removal from the chamber, expediting the sterilization process compared to traditional gravity displacement methods.

Achieving Speed Without Compromising the Efficacy of the Autoclave Sterilization Cycle

Efforts to optimize autoclave sterilization cycle speed without jeopardizing efficacy involve strategic measures:

- Pre-sorting ─ Categorizing items based on shared traits minimizes load complexity, contributing to swifter cycles.

- Routine maintenance ─ Consistent equipment maintenance and calibration uphold operational efficiency.

- Effective loading ─ Strategic arrangement of items within the autoclave bolsters steam penetration and distribution.

- Selective use of rapid methods ─ Employing rapid sterilization methods for certain instruments while adhering to traditional cycles for others maintains the equilibrium between speed and thorough sterilization.