Medical devices are delicate and intricately designed. Thus, ensuring their precision and reliability in manufacturing demands specialized welding techniques like TIG and laser welding. Consequently, precision medical device welding is critical in advancing medical device manufacturing and repairs.

Thus, precision medical welding technology helps enhance the quality and durability of vital medical tools, ranging from dental equipment to medical imaging equipment, such as MRI machines. That helps ensure their continued functionality and safety. The article explores the pivotal role precision medical welding plays, its diverse applications, and its profound impact on the healthcare industry.

-

Precision at the Core

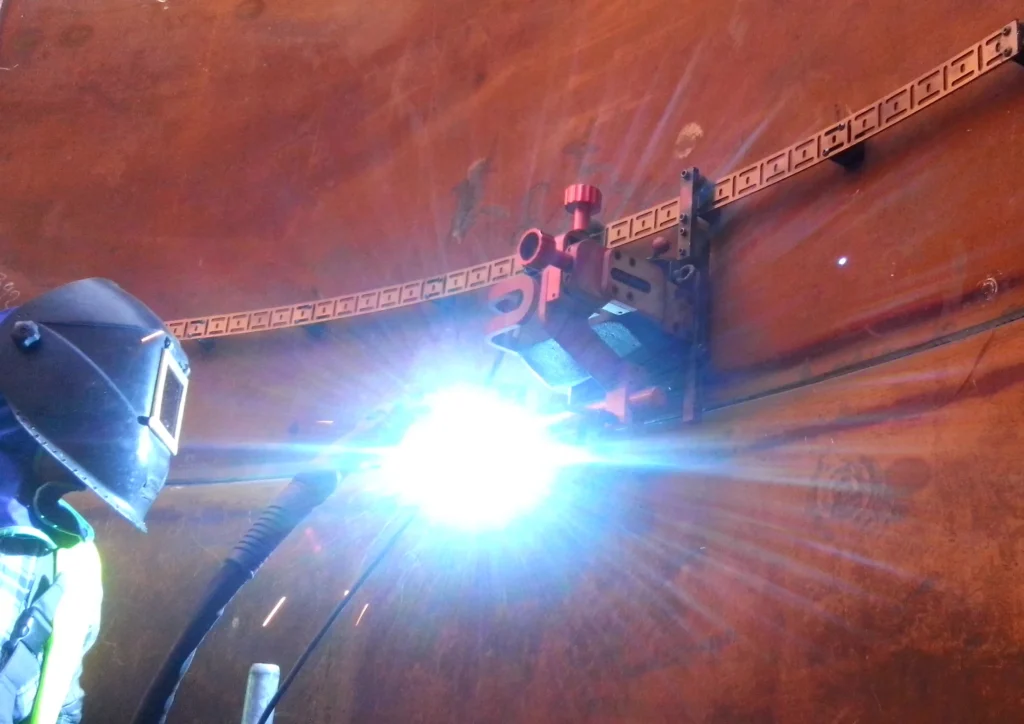

Central to medical device welding is the unwavering commitment to precision to ensure these critical instruments’ accuracy, reliability, and safety. The precision is vital because it provides the accuracy and reliability of essential components. In the manufacturing and repair of medical devices, where precision can be a matter of life and death, medical laser welding emerges as a game changer in achieving the highest levels of accuracy while adhering to the most stringent quality standards.

However, achieving this precision necessitates the expertise of experienced medical welding professionals who understand the intricacies of precision welding, guaranteeing that every joint meets the highest precision, quality, and safety standards. Thus, precision welding, mainly through methods like TIG and laser welding, is the cornerstone of excellence in medical device manufacturing.

-

Enhancing Quality Assurance

Medical device welding must consistently meet exacting standards, whether employing laser welding, TIG welding, or microscopic TIG welding. The welding process and its outcomes must strictly adhere to these standards to ensure quality assurance. ISO 13485 certification underscores this unwavering commitment to quality, delineating rigorous criteria for a quality management system in medical device manufacturing.

For instance, precision welding assumes vital significance in medical devices, where welds must create an impermeable seal, as exemplified in hermetic sealing for implantable devices like pacemakers and artificial joints. Adherence to these standards isn’t merely essential. It’s imperative in ensuring medical devices’ safety, reliability, and efficacy, thereby safeguarding patient well-being.

-

Medical Innovation Catalyst

Welding serves as a catalyst for innovation in the medical field, ushering in groundbreaking advancements. The precision and reliability of welding techniques, including laser welding, enable realizing once-unimaginable medical devices, thus propelling healthcare innovation. A critical role of medical welding is its collaboration with innovators, especially in prototyping and development.

Techniques like microscopic laser welding expedite the transformation of concepts into highly detailed and intricate medical device prototypes. The harmonious collaboration of expert medical welders and medical equipment innovators underscores the significance of prototypes in medical innovation, as they serve as a testing ground for novel ideas.

That ultimately contributes to the evolution and enhancement of healthcare solutions while shaping the future of healthcare. Medical welding experts like Micro Weld, Inc. seamlessly integrate into manufacturing, contributing to low reject rates and timely deliveries.

-

Versatility and Infusion of Advanced Medical Welding Technology

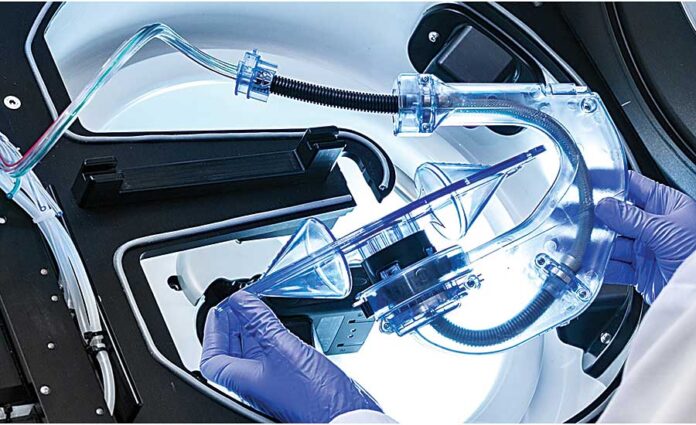

The versatility of medical welding techniques, including laser welding, TIG welding, and microscopic laser welding, shines through their wide-ranging applications within the healthcare industry. These methods find utility in crafting various medical devices, from surgical instruments and implants to precision welding for diagnostic equipment and catheters.

The adaptability underscores the importance of medical welding in addressing diverse healthcare needs. Simultaneously, the infusion of technological expertise is vital in ensuring the precision and reliability required in medical welding. Techniques like microscopic laser welding exemplify the fusion of advanced science and precision craftsmanship, maintaining the highest quality and safety standards critical for enhancing patient well-being.

Embrace High Standard Medical Welding for Enhanced Healthcare Solutions

Precision medical welding is a cornerstone in medical device manufacturing, research, and repairs, setting the bar for exacting standards. Partnering with an experienced medical welding company like Micro Weld, Inc. ensures precision and unwavering quality, ultimately safeguarding patient safety while supporting the research and development of cutting-edge medical innovations.

These precision welding techniques are crucial. They are the foundation of crafting intricate medical devices, essential for meeting the exacting standards the healthcare industry demands.