Screen printing, or silk screening, as it was traditionally known, is an old printing technique where a stencil was used to deposit dye on a piece of cloth made up of cotton, silk, etc.

Today the screen printing technique has evolved, and various fabrics can be used to create customized designs. Given the cost-effectiveness of the technique, many brands are using this technique to promote their brand.

However, that is not all; even small stores are taking steps to revive the old printing technique to sell beautifully designed clothes, especially T-shirts.

Screen printing is in itself quite affordable, but if this technique is to be used reliably for marketing purposes, the cost of production should be minimized.

There are many ways to make screen printing affordable, like purchasing from a traditional and reputable screen printing supply store.

What Exactly Is Silk Screening?

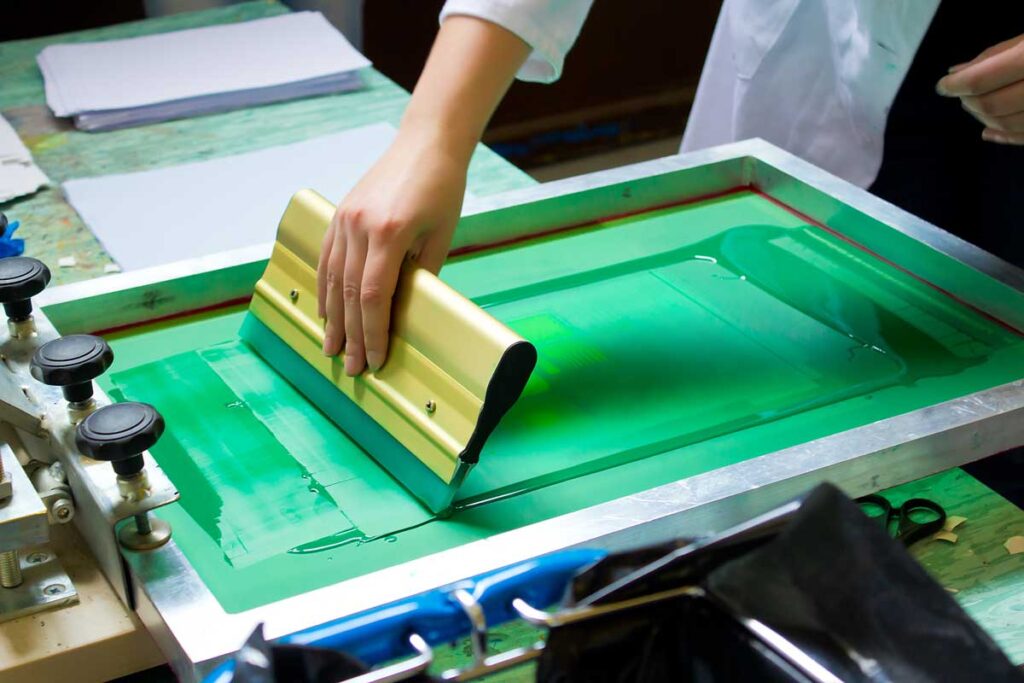

As the name suggests, a screen made up of plastics like polyester has a key role in this technique. This plastic (polyester) screen is coated with a dye sensitive to light. Since the dye is photo (light) sensitive, the coating process takes place in a dark room to avoid unintended exposure to stray light rays.

The dye coating step is followed by a burning step where the screen is burnt in such a fashion that the design or the shape of the stencil through which the dye needs to seep gets cut out on the screen.

This is followed by the dye deposition step, where the dye is deposited on the surface on which you want the final design (which may be a T-shirt, a banner, etc) after passing through the screen.

The final step in the process involves high-temperature treatment (curing) of the printed surface so as to bind the ink to the printed surface strongly.

How To Get Beautiful Screen Prints At Nominal Rates

When it comes to any printing technique, the quality of the raw materials, like the ink, the silk screen, or the adhesive, cannot be compromised.

In this blog post, we will discuss a few ways in which you can get good quality basic products in a way that fits your budget.

Visit A Reputable Supplies Store

There are a few distinct advantages of visiting a reputable supplier. First of all, they will offer good quality products; hence problems like bleed-through or the cracking of the dye will not be an issue if you follow all the guidelines correctly.

Secondly, most old suppliers understand the technique very well; they know the steps where a new person may go wrong. So apart from getting good quality raw material, you can get valuable advice on the right way of printing so that you create the best quality final product.

Some expert advice is always useful as getting the perfect print is quite a challenge, and a lack of knowledge about the right ink can create a bad end product despite putting in a lot of effort. Prints used in the printing technique can be of many types. Some of them are water-based and are known as discharge inks.

Apart from water-based dyes, there are other plastic-based dyes known as plastisols. The technique and the treatment required for each type of dye are different, and when you visit a reputable supplier, you will not miss out on the small nuances and thus save both raw material and money.

DIY Printing At Home

Most companies visit a professional printing store to get the screen printing done; however, if you can do it yourself, you not only learn a wonderful technique, but you can also do it in a more affordable way.

When you print at home, you can save at every step of the process, right from making the screen to the press that is used to transfer the ink on the printing surface.

-

Saving Money On The Screen

A single screen will cost around twenty to thirty dollars; however, the costs can be quite debilitating if you need multiple screens. So it is always advisable to start with single-color prints so that you can safely use only one screen for all your printing needs.

Once you become an expert or when you have a steady flow of customers, then you can invest more money in procuring multiple screens.

-

Saving Money On The Ink

Purchasing the inks can be very costly, but you can save money if you prevent wastage. One of the easiest ways to prevent wastage is to pour a small amount of ink initially and then keep pouring as needed.

This will ensure that you pour out only as much as you need and that nothing gets wasted.

-

Saving Money On Dark Room Lighting And Exposure Lighting

Many times, screens get damaged and wasted because they get exposed accidentally, so if you wish to save money, you must use safe light conditions in your dark room. Safelight conditions allow you to see what you are doing while coating the screen without exposing it to UV rays.

For the light in the exposure room, you can easily visit a local hardware shop and get the lights customized as per your needs. Exposure lights are usually 500 Watts or higher, with black housing and a clear glass lens in the front.

Conclusion

Getting the perfect print using a traditional printing technique like silk screening is difficult. Nonetheless, many people have realized the utility of this technique, and many small printing units are trying to master the art of silk screening.

However, perfecting old art is always expensive as there is a lot of waste at the initial stages. The cost of ink, stencil, exposure light, etc., can burden people with minimal resources.

But there are ways to overcome the cost and get wonderful designs even at low cost. So if people learn the nitty-gritty of the art, buy from wholesalers, or try to use DIY products, they can save a lot of money even when they are learning something new.