You will find numerous packaging designs available in the market. The most popular include in-mold labeling, screen printing, and adhesive labels. When the products are labeled properly, it makes the brand stands out from its competitors. On the contrary, if the label comes off the parcel easily because of poor adhesion, it may have a bad impression on your customers.

To treat these adhesive problems, surface treatments must be used. Flynn Burner Corporation uses the best technology for addressing printing and labeling issues. Flame treatment is one of the most popular surface treatment methods. This article will teach you about flame treatment and its versatile applications.

What Do You Mean By Flame Treatment?

In simple terms, flame treatment is a process in which the surface of the plastic container is modified using chemicals to improve its adhesion properties. Plastic material often has low surface energy and is incapable of properly sticking labels, glues, and inks to its surface. To treat this problem, industries have come up with a solution: flame treatment.

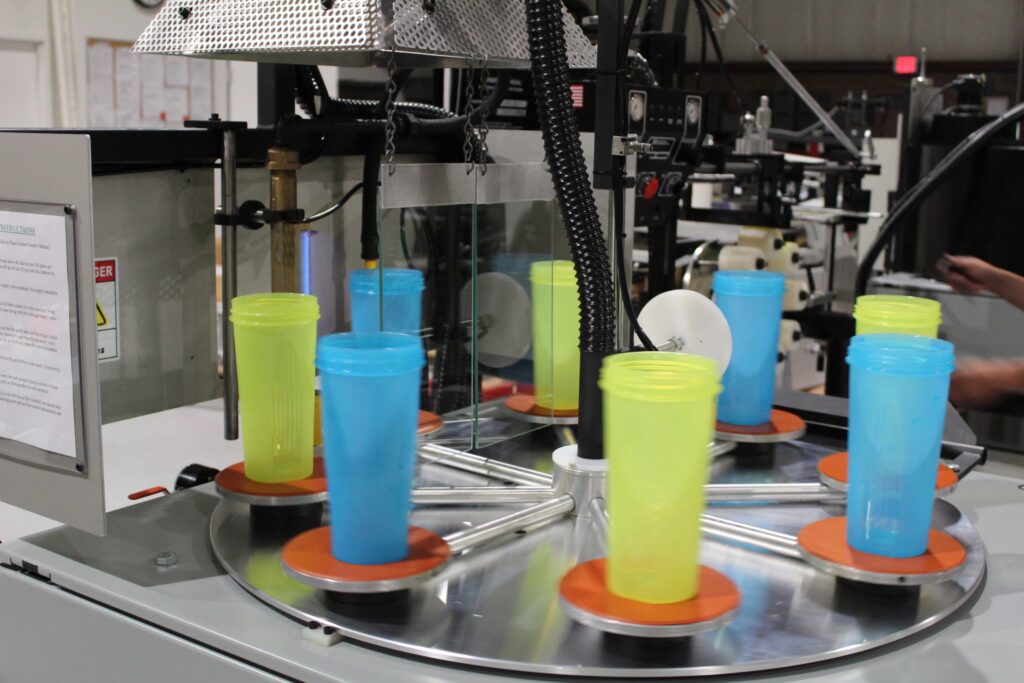

In this process, specifically established equipment is used to build a controlled mixture of air and natural gas to produce flames. The surface of the container is exposed to this flame for about 0.2-0.3 seconds. With the help of this surface treatment, all the dirt particles and other contaminants are removed to improve the container’s adhesion.

Flame treatment modifies plastic containers to increase their surface energy, and materials like inks, labels, and glues can stick to them better.

Working On Flame Treatment

The first step is to produce the flame using a piece of special equipment. It is produced by a combination of air and natural gas in a controlled manner. The flame is then directed onto the material’s surface for a very short period. During this process, the plastic surface’s molecular chains break, and the flame’s active ions bond to the material’s surface. Originally, the surface is nonpolar, and after this treatment, it becomes polar.

Opposite surfaces have better adhesion properties than the nonpolar ones. It means that glues, inks, and labels can easily stick to polar materials. Choosing the right burner is an important step in this process. Pick a burner that can effectively adjust the quantity of air and natural gas in the mixture. Adjusting the proportions of the natural gas and air is essential to produce adequate oxygen.

Common Uses The Flame Treatment

This surface treatment process is used in both small industries and large industries. An example of a small industry includes creating perfume bottles, and a large industry includes building construction materials.

The most common use of this process is to improve the adhesivity of all types of vehicles to paint them properly. This process is generally used on the plastic surfaces of automobiles that require painting. It is also used for activation and degreasing the metal portions before labeling them. You can also use this process for painting and printing in construction.

Ceramic and glass painting also becomes easier with flame treatment. This process can effectively apply Any coating or paint on glass surfaces. It is because the adhesive property of the ceramic and glass material improves with this surface treatment. Most manufacturers apply this process to glass bottles to make decorative designs on them.

Versatile Applications Of Flame Treatment

Here are some special applications where flame treatment is utilized:

Coupling of steel and aluminum foil using polymer material:

When you see a microscope to see the aluminum foil, you will find various imperfections on its surface. It may look like these sheets have great adhesion properties, but it is not true. Flame treatment can help clean oil traces formed by the lamination on aluminum sheets.

Textile industry for peeling:

The textile industry also uses flame treatment for peeling synthetic or artificial materials. The process is used to treat tapes and thin sheets that are used as end products in the textile industry.

Plastic containers to improve adhesion:

If the paint sticks to the plastic container, you can only create beautiful flower vases. With the flame treatment’s help, the plastic containers’ adhesivity improves. It means the paint sticks to the container easily to produce various decorative items. You can utilize this process to create various plastic items for decoration purposes.

Advantages Of The Flame Treatment

Apart from improving the material’s adhesive properties, it has various other benefits. These advantages include:

- Flame treatment uniformly treats the surfaces of the containers. It means that the glue, ink, and labels can stick to these materials without forming any gaps.

- Many people think this surface engineering process may damage the containers, but this is untrue. It doesn’t distort, char, or destroy the plastic materials as the heat is applied for a very short period.

- Various surface treating methods are available in the market, such as plasma activation, chemical, and corona. But out of all these methods, flame treatment needs the least expensive equipment.

- Another advantage is that the flame utilized in this process can be produced with easily accessible products such as coal gas, methane, propane, and butane. It doesn’t require any specific chemical for its working.

- This process helps increase the durability between the material’s surface and the sticking label. The labels will last long after applying this process to the container.

To Sum Up

Most plastic containers have low surface energy, making them incapable of properly sticking glue, inks, and labels to them. Flame treatment increases surface energy and improves the material’s adhesive properties.

In this process, a piece of special equipment is used to produce a mix of natural gas and air in a controlled manner. The excess oxygen produced is then exposed to the material’s surface for a short time. This process is used for making perfume bottles, glass vases, and the construction industry. Apart from this, it has some versatile applications as well. Check out the above points to understand more about this process and its uses.